|

Place of Origin: |

Tengzhou China |

|

Brand Name: |

Zhongyou |

|

Model Number: |

YQ32-315T |

|

Certification: |

CE ISO |

|

Minimum Order Quantity: |

1 |

|

Packaging Details: |

The sample includes a hydraulic press and mold. Please contact us for more details. |

|

Delivery Time: |

15-45 day |

|

Payment Terms: |

L/C D/P D/A T/T |

|

Supply Ability: |

50set/m |

Zhongyou 315 ton four-column hot press hydraulic press is a specialized machine for manufacturing Kevlar and aramid fiber bulletproof helmets. The machine has strong pressure, very high pressing accuracy, and precise temperature control system, which can meet the pressure and temperature required for pressing helmets. Depending on the material and specifications of the product, we can also provide other models of hydraulic presses.

Regular model parameters for reference only. We support customisation on demand.

|

YQ32 Technical Parameters |

||||||||

|

|

Unit |

YQ32—63 |

YQ32—100A |

YQ32—100B |

YQ32—200A |

YQ32—200B |

YQ32—315A |

YQ32—315B |

|

Nominal force |

KN |

630 |

1000 |

1000 |

2000 |

2000 |

3150 |

3150 |

|

Maximun system pressure |

Mpa |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

|

Max.open height |

mm |

700 |

800 |

900 |

900 |

1100 |

1000 |

1250 |

|

Max Stroke of Slider |

mm |

400 |

500 |

600 |

600 |

700 |

600 |

800 |

|

Effective table size |

mm |

610×500 |

630×550 |

750×700 |

800×800 |

1000×1000 |

800×800 |

1260×1160 |

|

Down speed |

mm/s |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

|

Pressing speed |

mm/s |

11~22 |

7~15 |

7~15 |

7~18 |

7~18 |

7~12 |

7~12 |

|

Return speed |

mm/s |

80 |

90 |

90 |

90 |

90 |

90 |

100 |

|

Ejection cylinder force |

KN |

100 |

200 |

200 |

400 |

400 |

630 |

630 |

|

Stroke of ejection cylinder |

mm |

160 |

200 |

200 |

200 |

200 |

300 |

300 |

|

|

|

|

|

|

|

|

|

|

|

|

Unit |

YQ32—400 |

YQ32—500 |

YQ32—630 |

YQ32—800 |

YQ32—1000 |

YQ32—1250 |

YQ32—1600 |

|

Nominal force |

KN |

4000 |

5000 |

6300 |

8000 |

10000 |

12500 |

16000 |

|

Maximun system pressure |

Mpa |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

|

Max.open height |

mm |

1250 |

1500 |

1500 |

1500 |

1500 |

1500 |

1500 |

|

Max Stroke of Slider |

mm |

800 |

900 |

900 |

900 |

900 |

900 |

900 |

|

Effective table size |

mm |

1260×1160 |

1400×1400 |

1500×1500 |

1600×1600 |

1600×1600 |

1600×1600 |

1600×1600 |

|

Down speed |

mm/s |

100 |

150 |

150 |

180 |

180 |

180 |

190 |

|

Pressing speed |

mm/s |

5~11 |

10~18 |

9~18 |

9~18 |

10~18 |

6~15 |

6~14 |

|

Return speed |

mm/s |

100 |

180 |

200 |

180 |

220 |

200 |

220 |

|

Ejection cylinder force |

KN |

630 |

1000 |

1000 |

1000 |

1000 |

1000 |

1600 |

|

Stroke of ejection cylinder |

mm |

300 |

300 |

300 |

300 |

300 |

300 |

300 |

Hot press molding of various composite materials such as Kevlar, aramid fiber, BMC, SMC, FRP, PE, etc.

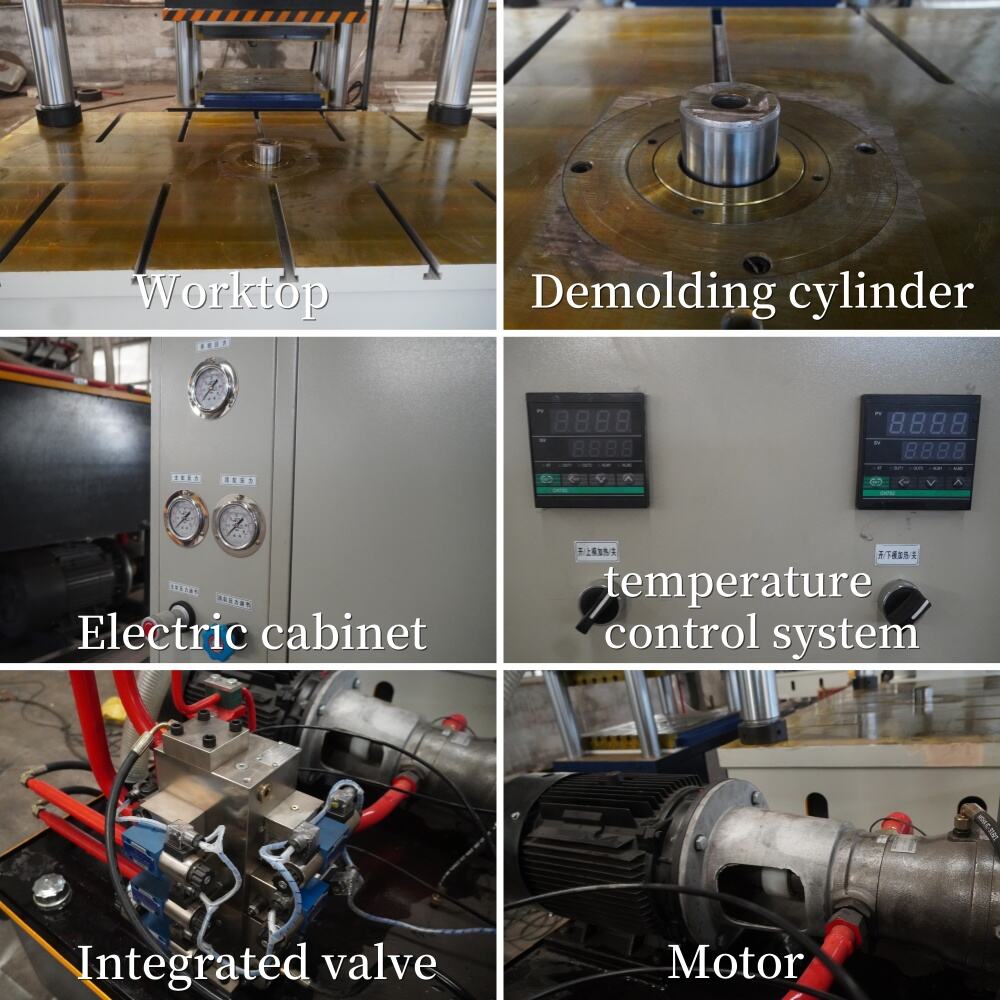

1.Three-beam, four-column structure: Provides stable structure, high precision, and ample operational space.

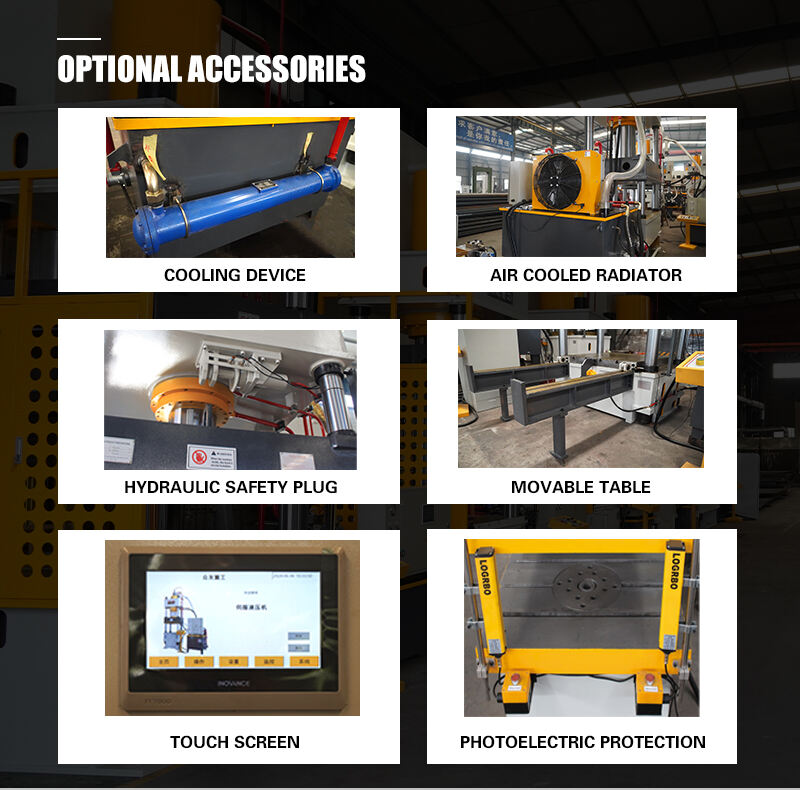

2.Advanced hydraulic system: Features integrated cartridge valves, and the electrical system uses brand-name components for high-precision pressing, reliable quality, and easy maintenance.

3.Equipped with a PLC (Programmable Logic Controller) and a temperature controller, it can precisely control the pressing accuracy and the mold temperature.

4.Button control: Simple to operate.

5.Adjustable parameters: Pressure, stroke, and holding time can be adjusted.

6.Scientific design: Simple structure, easy to maintain.

We provide comprehensive after-sales services, including equipment installation, debugging, and operation training. Hydraulic press operation manuals are provided to facilitate user learning and maintenance.

Copyright © Zhongyou Heavy Industry Machinery Equipment Co.,Ltd. All Rights Reserved