|

Post ta' Origine: |

Tengzhou Ċina |

|

Ism Brand: |

ZHONGYOU |

|

Numru Model: |

YQ32-1000T |

|

Certifikat: |

CE ISO |

|

Kwantità minima għall-ordni: |

1 |

|

Dettagli tal-Pakkagin: |

Isampul jinkludi pressa idrolikika u mold. Tgħallaxna għal ħafna dettagli. |

|

Tajp tal-konsegna: |

15-45 jum |

|

Termini tal-pagament: |

L/C D/P D/A T/T |

|

Għalba tal-Fornitura: |

50set/m |

Ħa ġejja problema?

Jekk jogħġbok tikkontattina biex nisdiżju!

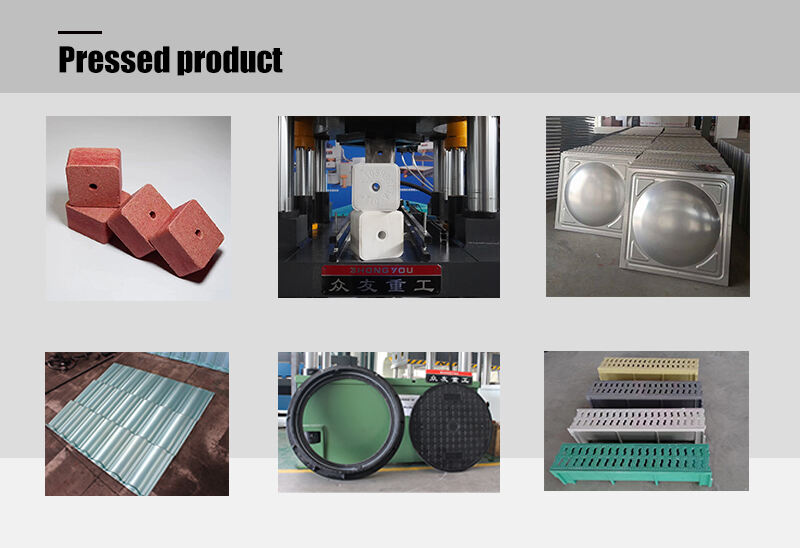

Il-prem id-dritt jippermetti l-formazzjoni bil-għajnuna tal-tankhi tal-ilma SMC matul dizajn meqblu biċċilindri id-debbiegħa, li jippermettu distribuzzjoni aktar mibbilja tal-prem u li tista' tkun utli għall-iksemplifikar prodotti kbir. Il-ċċilindri id-debbiegħa jagħmlu prem ta' 1000 tonni. Il-kontrollur PLC u il-kontrollur ta' temperaturajġu l-mašina aktar intelligenzi, ippermettendu kontroll preciż ta' prem u temperaturi biex jikkonferma li prodotti jassolu l-qualità aħjar.

|

Parametri Teknikijiet tal-YQ32 |

||||||||

|

|

unità |

YQ32—63 |

YQ32—100A |

YQ32—100B |

YQ32—200A |

YQ32—200B |

YQ32—315A |

YQ32—315B |

|

Forza nominale |

KN |

630 |

1000 |

1000 |

2000 |

2000 |

3150 |

3150 |

|

Pressjoni massima tal-sistema |

MPa |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

|

Għada massima għall-apertura |

mm |

700 |

800 |

900 |

900 |

1100 |

1000 |

1250 |

|

Corsa massima tal-slajder |

mm |

400 |

500 |

600 |

600 |

700 |

600 |

800 |

|

Dimanzi tal-taċċa effettiva |

mm |

610×500 |

630×550 |

750×700 |

800×800 |

1000×1000 |

800×800 |

1260×1160 |

|

Vloċta għall-isfor |

mm/s |

100 |

100 |

100 |

100 |

100 |

100 |

100 |

|

Vloċta għall-pressja |

mm/s |

11~22 |

7~15 |

7~15 |

7~18 |

7~18 |

7~12 |

7~12 |

|

Veloċità tar-ritorn |

mm/s |

80 |

90 |

90 |

90 |

90 |

90 |

100 |

|

Forza tal-inklustra tal-bidla |

KN |

100 |

200 |

200 |

400 |

400 |

630 |

630 |

|

Ħadd ta' inklustrazzjoni tal-bidla |

mm |

160 |

200 |

200 |

200 |

200 |

300 |

300 |

|

|

|

|

|

|

|

|

|

|

|

|

unità |

YQ32—400 |

YQ32—500 |

YQ32—630 |

YQ32—800 |

YQ32—1000 |

YQ32—1250 |

YQ32—1600 |

|

Forza nominale |

KN |

4000 |

5000 |

6300 |

8000 |

10000 |

12500 |

16000 |

|

Pressjoni massima tal-sistema |

MPa |

25 |

25 |

25 |

25 |

25 |

25 |

25 |

|

Għada massima għall-apertura |

mm |

1250 |

1500 |

1500 |

1500 |

1500 |

1500 |

1500 |

|

Corsa massima tal-slajder |

mm |

800 |

900 |

900 |

900 |

900 |

900 |

900 |

|

Dimanzi tal-taċċa effettiva |

mm |

1260×1160 |

1400×1400 |

1500×1500 |

1600×1600 |

1600×1600 |

1600×1600 |

1600×1600 |

|

Vloċta għall-isfor |

mm/s |

100 |

150 |

150 |

180 |

180 |

180 |

190 |

|

Vloċta għall-pressja |

mm/s |

5~11 |

10~18 |

9~18 |

9~18 |

10~18 |

6~15 |

6~14 |

|

Veloċità tar-ritorn |

mm/s |

100 |

180 |

200 |

180 |

220 |

200 |

220 |

|

Forza tal-inklustra tal-bidla |

KN |

630 |

1000 |

1000 |

1000 |

1000 |

1000 |

1600 |

|

Ħadd ta' inklustrazzjoni tal-bidla |

mm |

300 |

300 |

300 |

300 |

300 |

300 |

300 |

1.Struttura tal-tliet barri u erbgħa kolonna: Forni struttura stabbil, prezzjoni elevata, u spazju operattorju abbundanti.

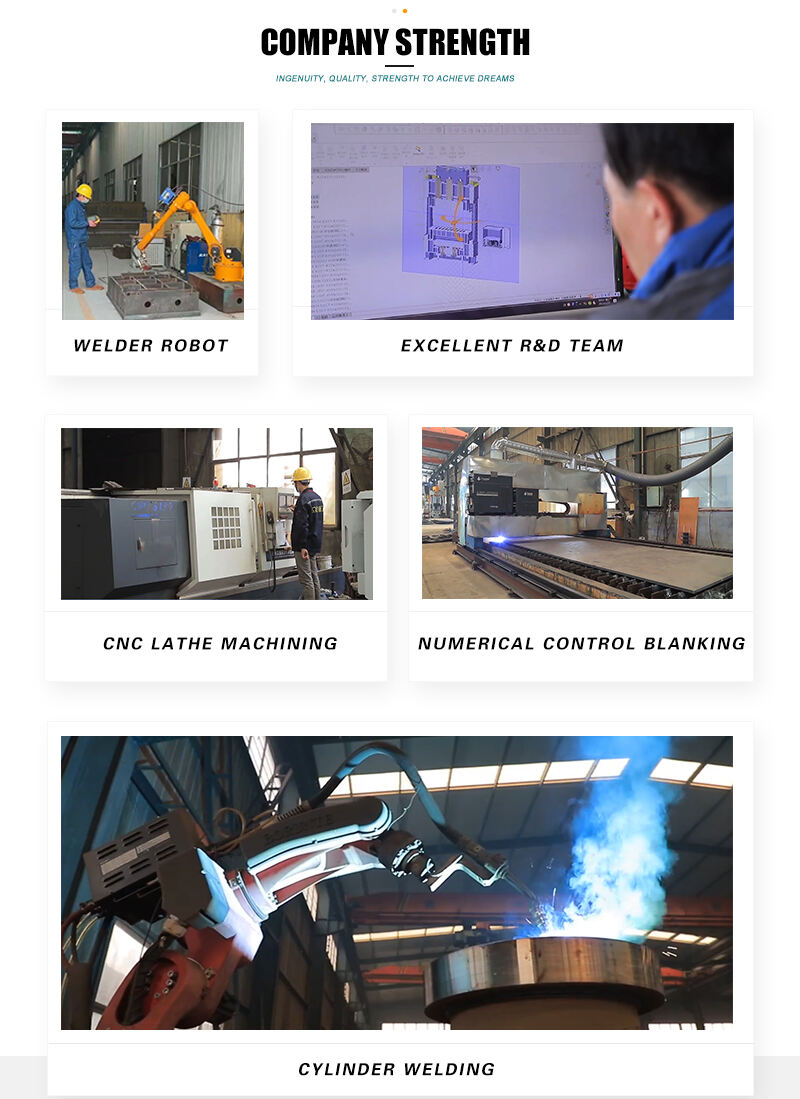

2.Sistema idratiku avanzat: Ikkaratterizza b’valvijiet kartsuna intigrazzjoni, u s-sistema elettriku jista' ikkompone komponenti brand-name għal prezzjoni ta' prezzjoni preciża, kwality relijabili, u mantieniment ġejj.

3.Munit meħtieq bi PLC (Programmable Logic Controller) u kontrollur ta' temperatura: jistgħu jagħmlu kontroll preciż tal-accurazzjoni tal-pressjarikew u tar-temperatura tal-mold.

4.Kontroll ta' buttuni: Semplici għall-operazzjoni.

5.Parametri aġġustabili: Pressja, spostament, u temp ta' retenzjoni jistgħu jkunu maħluqi.

6.Dizajn Scientifiku: Struttura semplice, ġejja għall-konservazzjoni.

Niżżemu servizzi komprehensivi post-vendi, inklużivment l-inkistazzjoni tal-ekipament, it-tastiera, u l-istruzzjoni operattiva. Jippermettu manwalijiet għall-operazzjoni tal-pressi idroliki biex jagħmlu li l-utenti jissirja u jixtieqdu.

L-istrut Zjongyou Machinery gandha aktar minn 20 snin ta' esperjenza fil-produzzjoni tal-pressi idratik. Nifforžu kliet preffi kompli tal-equipment idratik meħtieq bil-numru kbir ta' soluzzjonijiet madurat ta' dizajn u kasi sfikessati mal-klijenti. Niktbir ukoll servizz ta' kustomizzazzjoni, inklużivment il-mold u l-equipment tal-linja ta' produzzjoni relatati, offrendo soluzzjonijiet kumpleti. Ma tis-sammeċċa li tikkontattina għal informazzjoni aktar.

Copyright © Zhongyou Heavy Industry Machinery Equipment Co.,Ltd. All Rights Reserved